Basic Info.

Transport Package

Standard Packaging

Specification

Customized

Trademark

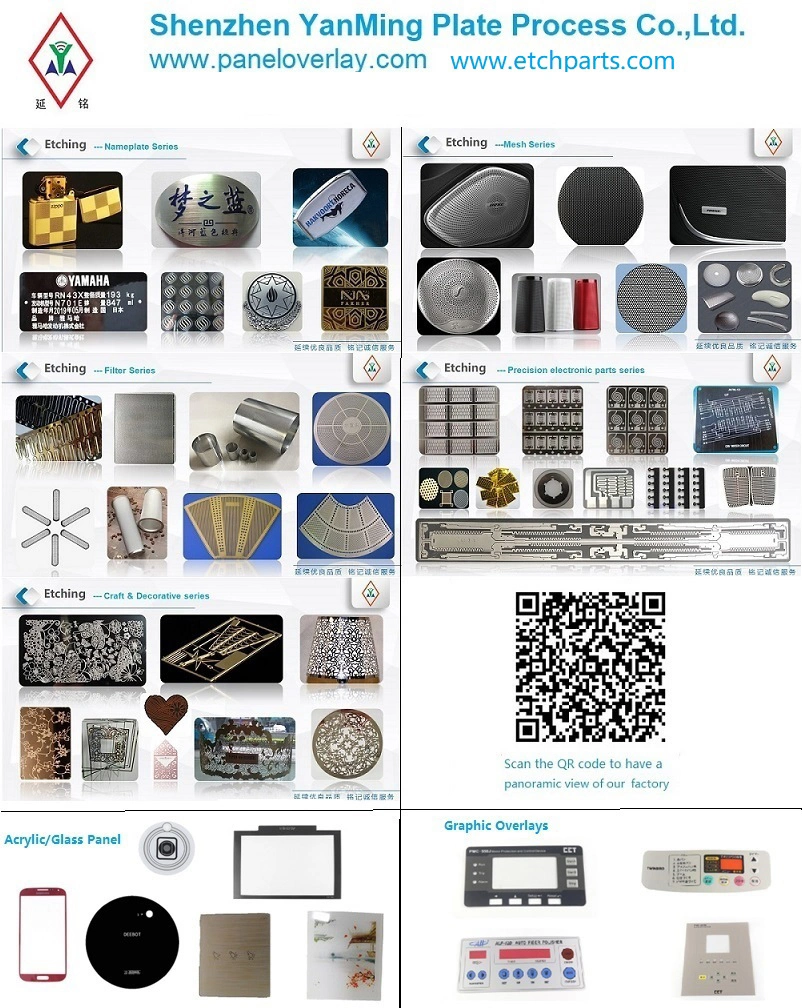

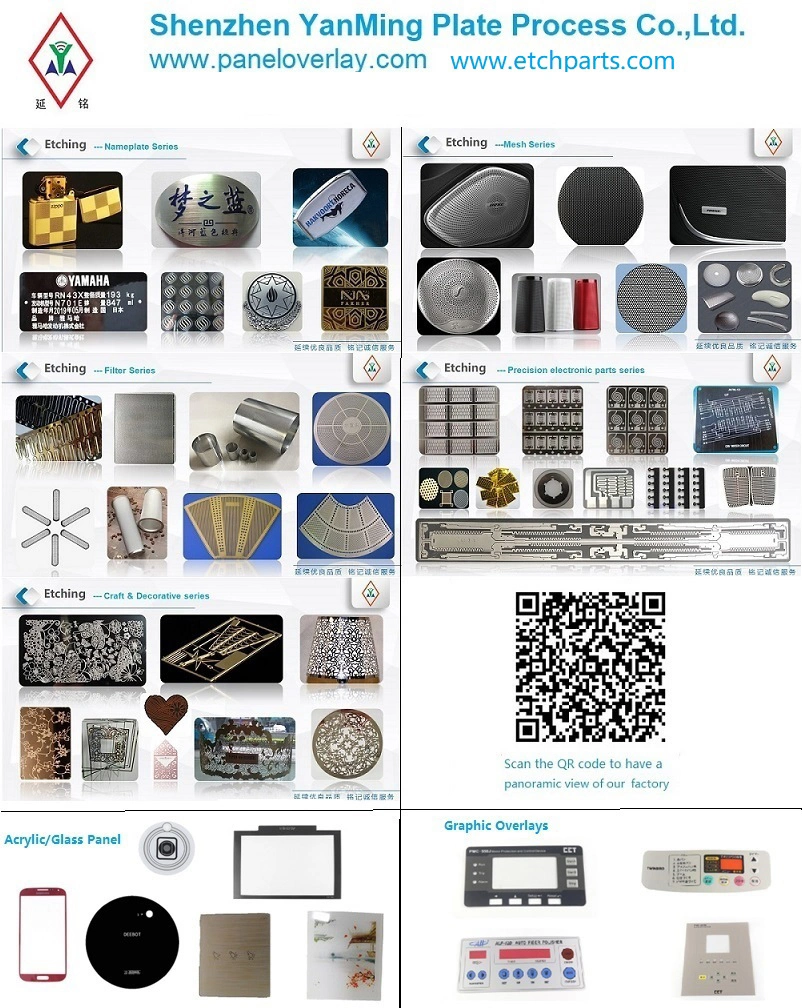

YM Etching Product

Origin

China

Production Capacity

100, 000 PCS/Week

Packaging & Delivery

Package Size

50.00cm * 10.00cm * 1.00cm

Package Gross Weight

0.100kg

Product Description

Products Description

| Material | Aluminum, SS or as your requirements | Model Numble | YM-DSP |

| Color | Silver or Customized | Technique | Etching or Customized |

| Thickness | Customized | Specification | Customize |

| Quality | 100% Tested | Length | Customize |

| Shape | Customize | Size | Customize |

| Application | Car Door Sill | Surface Treatment | Anodized, Polished or as your requirements |

| Sample | 5 days | Certificate | ISO 9001 & ISO 14001 |

| Feature | Durable, Anti-scratch | Origion | Shenzhen, Guangdong, China |

1.Photo-etching has been widely used in the manufacturing of car loudspeaker mesh grilles, many branding car manufacturers

or loudspeaker manufacturer benefit from this technology, as it features:

1,Low tooling cost, no need for expensive DIE/Mould -- prototype normally costs only hundred dollars.

2, Design flexibility -- Photo etching allows much flexibility on product design no matter it is product outer shape or the hole patterns, there is even no cost for complex

designs.

3, Stress and burr free, smooth surface -- the material temper will not be affected during this process and it can guarantee a very smooth surface.

4, Easy to coordinate with other manufacturing processes such as PVD plating, stamping, brushing, polishing and so on.

5, Various material options -- stainless steel, copper, brass, aluminum, titanium, metal alloy at the thickness from 0.02mm to 2mm are all available.

Your competitors are using photo etching to supply better products now...Why not have a try?

2. Applicable Scope:

1. etching processing various kinds of metal, metal and alloy and stainless steel plate, strip,

2. (1), petroleum, chemical, food, pharmaceutical precision filter, filter plate, filter canister,filters,

(2)electronic industry with metal plate, plate leakage, lead, lead frame, metal substrate,

(3) precision optical and mechanical parts, components, plane spring,

(4) friction slices and other parts of concave and convex surface,

(5) metal plate and the design of complex metal accessories and elegant handicraft.

3. Applicable Materials: Stainless steel sheet, copper sheet, aluminum foil, ferronickel alloy, iron sheet, Nickel silver,

titanium alloy, etc.

4. Production Capability: Capable of shaping varieties of materials with the thickness of 0.03 to 1.2mm such as stainless steel, copper, aluminum, zinc and iron sheet by

etching, half-etching, both sides and pattern imprinting without the need of hardware mold manufacturing charge.

5. Production Process: Film(CAD output) →get the materials ready→Pre-treatment→DRY FILM(Lamination)→Exposure→Developing→Drying→Etching→Stripping

→ Checking,Packing,Delivery

6. Characters: precision etching, smooth surface on both edges, no embossment, no convexconcave, no burnisher burr, no warping, any complicated pattern or

geometric figure is available.

or loudspeaker manufacturer benefit from this technology, as it features:

1,Low tooling cost, no need for expensive DIE/Mould -- prototype normally costs only hundred dollars.

2, Design flexibility -- Photo etching allows much flexibility on product design no matter it is product outer shape or the hole patterns, there is even no cost for complex

designs.

3, Stress and burr free, smooth surface -- the material temper will not be affected during this process and it can guarantee a very smooth surface.

4, Easy to coordinate with other manufacturing processes such as PVD plating, stamping, brushing, polishing and so on.

5, Various material options -- stainless steel, copper, brass, aluminum, titanium, metal alloy at the thickness from 0.02mm to 2mm are all available.

Your competitors are using photo etching to supply better products now...Why not have a try?

2. Applicable Scope:

1. etching processing various kinds of metal, metal and alloy and stainless steel plate, strip,

2. (1), petroleum, chemical, food, pharmaceutical precision filter, filter plate, filter canister,filters,

(2)electronic industry with metal plate, plate leakage, lead, lead frame, metal substrate,

(3) precision optical and mechanical parts, components, plane spring,

(4) friction slices and other parts of concave and convex surface,

(5) metal plate and the design of complex metal accessories and elegant handicraft.

3. Applicable Materials: Stainless steel sheet, copper sheet, aluminum foil, ferronickel alloy, iron sheet, Nickel silver,

titanium alloy, etc.

4. Production Capability: Capable of shaping varieties of materials with the thickness of 0.03 to 1.2mm such as stainless steel, copper, aluminum, zinc and iron sheet by

etching, half-etching, both sides and pattern imprinting without the need of hardware mold manufacturing charge.

5. Production Process: Film(CAD output) →get the materials ready→Pre-treatment→DRY FILM(Lamination)→Exposure→Developing→Drying→Etching→Stripping

→ Checking,Packing,Delivery

6. Characters: precision etching, smooth surface on both edges, no embossment, no convexconcave, no burnisher burr, no warping, any complicated pattern or

geometric figure is available.

Etching Process

Packaging & Shipping

Packing: Standard Packaging or as your requirement.

Shipping: Normally by express/Air/Sea .

Port: Shenzhen Port

Lead Time:

| Quantity(Pieces) | 1-1000 | >1000 |

| Est. Time(days) | 7-10 | Negotiable |

Company Profile

| Business Type | Manufacturer, Trading Company | Country / Region | Guangdong, China |

| Main Products | Control panel graphic overlays, Acrylic/Glass panel, Nameplates and Metal etching parts etc. | Year Established | 2006-03-22 |

| Total Employees | <50 | Main Markets | Domestic Market 70.00% Africa 4.00% South America 3.00% |

| Certifications | Excellent Supplier of 2016 ISO9001 ISO14001 | Total Annual Revenue | US$2.5 Million - US$5 Million |

1, 5000m2 standard own-built factory with wastewater treatment system

2, ISO9001, ISO14001 and TS16949 certificated

3, With 8 experienced engineers and professional QC team

4, Imported etching machine and Auto 2D inspection machine

5, Seven vertical etching line and Seven horizontal etching line

6, Fully inspection and quality checking before shipment

Value-added service: stamping, PVD plating, coating, brushing, polishing, etc...

Our goal is to offer one-stop manufacturing solution for our valuable customers, saving their time and money, we always keep working on the quality improvement to reach zero defects and 100% customer satisfaction.

Your expert for solution!

We Shenzhen Yanming Plate Process Co., Ltd. is professionally customize manufactoring various types of front panel, control panel graphic overlays and nameplates etc. with different materials from 2006, benefit from our production capacity, fast delivery, good quality control and after service, now we are the first class supplier for many partners in China and abroad.

Each product may be customized according to your requirements with varying options for materials and manufacturing processes like screen printing, offset printing, laser marking, laser cutting, photosensitive imaging, embossing, stamping, chemical etching, digital printing engraving etc, a variety of adhesives and finishes are available to complete your product, we constantly strive to provide customers with quality service and production.

We Shenzhen Yanming Plate Process Co., Ltd. is professionally customize manufactoring various types of front panel, control panel graphic overlays and nameplates etc. with different materials from 2006, benefit from our production capacity, fast delivery, good quality control and after service, now we are the first class supplier for many partners in China and abroad.

Each product may be customized according to your requirements with varying options for materials and manufacturing processes like screen printing, offset printing, laser marking, laser cutting, photosensitive imaging, embossing, stamping, chemical etching, digital printing engraving etc, a variety of adhesives and finishes are available to complete your product, we constantly strive to provide customers with quality service and production.

Machinery Equipment

Certifications

Why Choose Us

Shenzhen YanMing Plate Process Co.,Ltd is a flexible and innovative service provider.

1. We can provide you good quality products with factory price.

2. We will reply to your inquiry as soon as possible.

3. Patient and professional sales team.

4. Delivery on time.

5. Our products are highly appreciated by customers from many countries.

6. We are factory manufacturer, and welcome your designs or ideas!

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.Q: How long is your delivery time?

Q: Do you provide samples ? is it free or extra ?

Q: What is your terms of payment ?

Your inquiry and visit would be welcomed very much!

Other Products

2. We will reply to your inquiry as soon as possible.

3. Patient and professional sales team.

4. Delivery on time.

5. Our products are highly appreciated by customers from many countries.

6. We are factory manufacturer, and welcome your designs or ideas!

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. Or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance , balance before shippment.

Your inquiry and visit would be welcomed very much! Other Products